BallistiX Overview

Developed originally as a petroleum-proof anti-aggregate agent. BallistiX has been tailored to provide a long-lasting, stunningly beautiful, sustainable and non-sacrificial finish that protects these surfaces from abrasive wear, microbial growth, odor and chemical attack. BallistiX is a Silico-Ceramic-Silane-Hybrid coating.

Why BallistiX?

- Unparalleled protection against spalling, pitting, erosion and chemical damage

- Prevents mold and mildew food sources of organic materials

- Reduces saponifying action of water and alkali resulting in premature or accelerated erosion

- Repels chemicals to prevent staining and disfiguring

- Clean-ability, anti-graffiti

- Non-slip (wet slip coefficient >0.80)

- Mold/mildew protection

- Color enhancement

- Impregnating “wet look” sealer on dull or matte surfaces such as for pool decks, pavers, sidewalks and more

- Non-film forming clear siloxane water repellent for water and stain

BallistiX Applications

- Indoor/Outdoor

- Vertical, horizontal

- Industrial, residential

- Raw concrete, finished, stained, or finishing system for diamond polishing

- Tile and grout flooring and surfaces

- Epoxy surfaces, resinous coatings, countertops, liquid ceramic

- Vinyl flooring and surfaces (Ranger products only)

BallistiX Technology

BallistiX Coatings Are Engineered As:

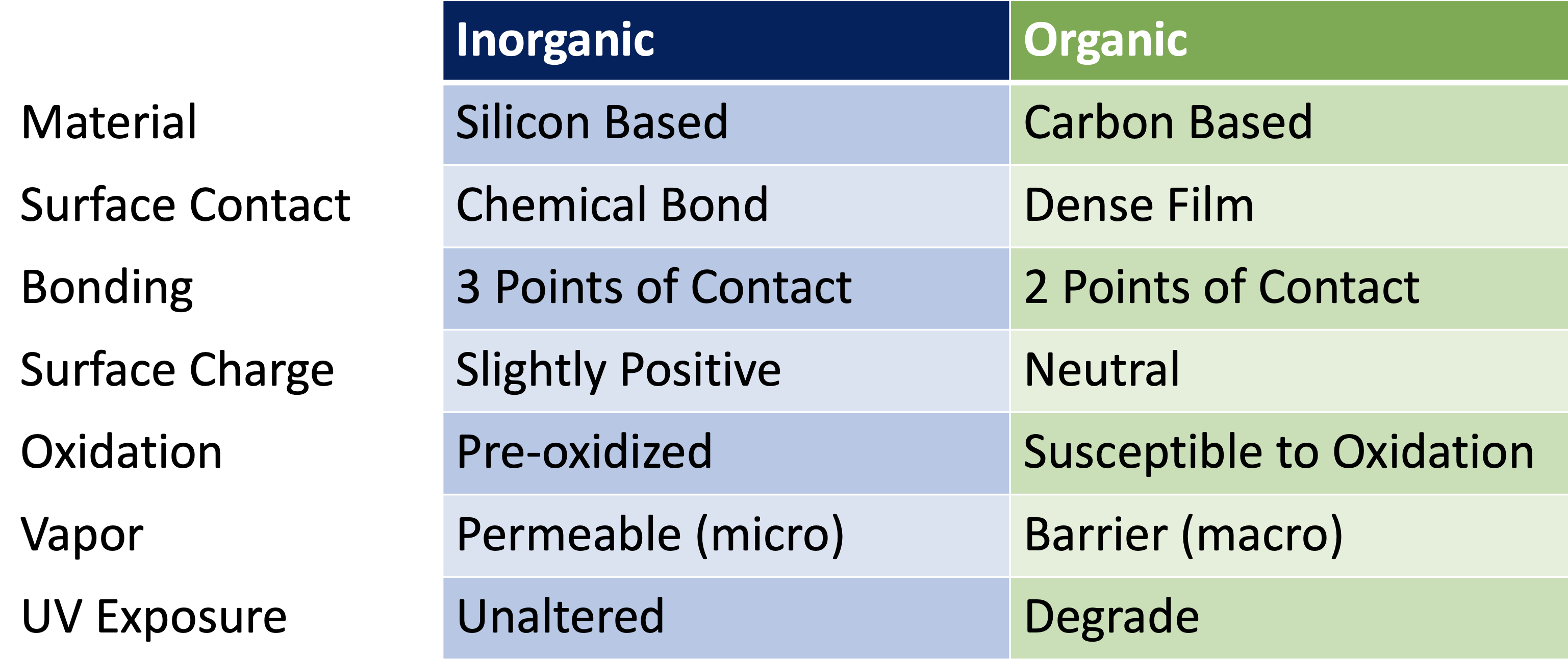

- Inorganic

- hydrophobic

- heat resistant to 1200 degrees Fahrenheit

- impervious to UV – Cool to touch!

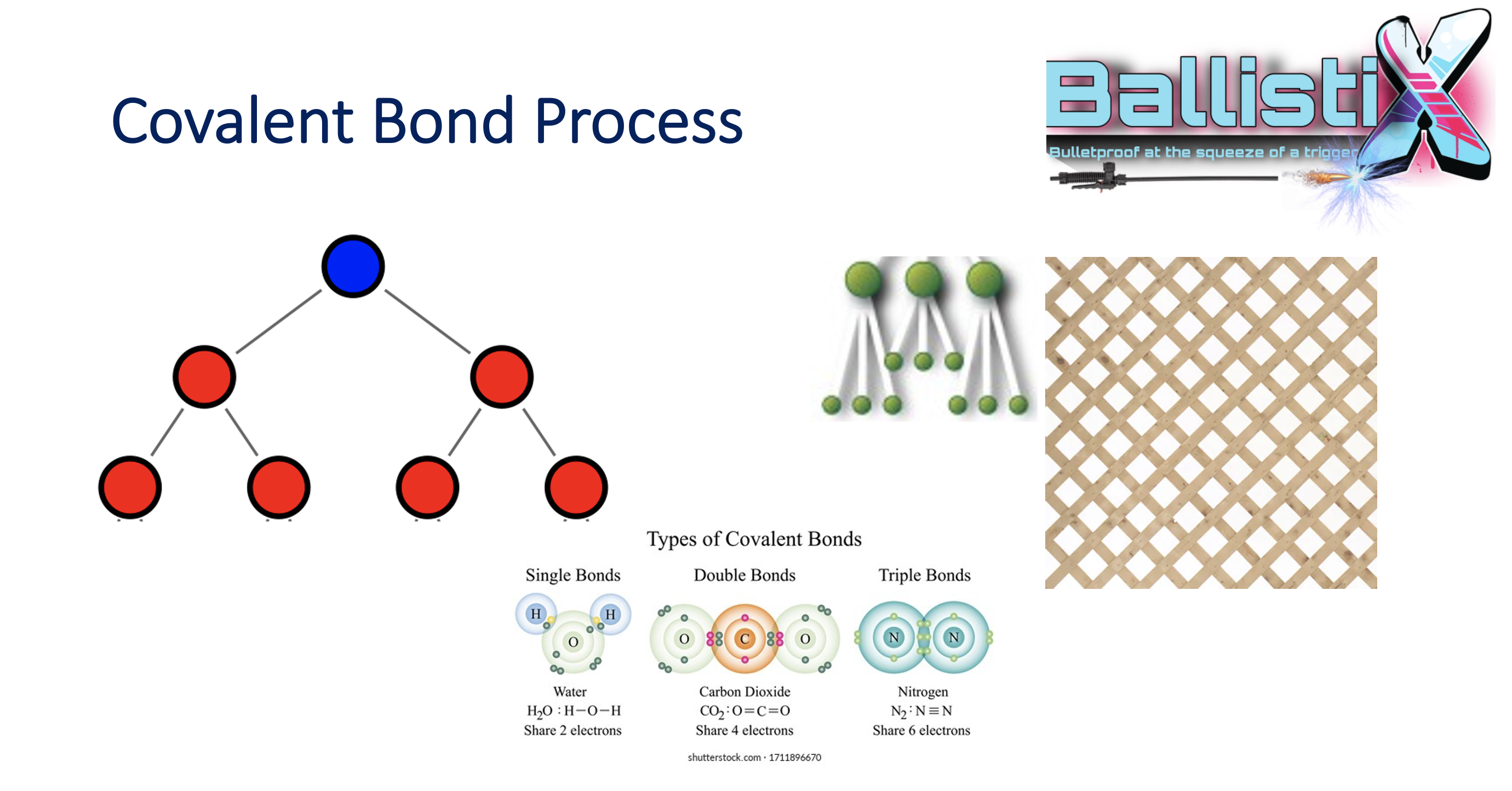

- Covalent Bonds

- Bonds to all surfaces

- Nano-technology

- Non-porous, very smooth surface

- Resistant to chemical corrosion

BallistiX products are specially designed to have a chemical reaction with the surface they are applied. The result of that reaction forms a very strong bond called a molecular or covalent bond. The chemistry behind this technology allows the surface coating to create a unique fusion (covalent bonding) between the treatment and the substrate to be protected. This bond is nearly unbreakable!

BallistiX Inorganic Silicon Coatings:

- bonds contain three points of contact

- anchored at three points is far stronger than only being anchored at two points.

- exhibits a slightly net positive charge

- repels foreign material away from the surface of the bonds

- pushes away the electrolyte and the environmental factors that amplify the corrosive effect.

- helps pump away the negative electrolyte as well as the oxygen itself

- keeps the already pre-oxidized surface free from the negative effects caused by extreme outside environmental influences

BallistiX Innovations

The business value of using BallistiX coatings is realized in several areas. It’s longer-lasting because we chemically bond to the surface. BallistiX also provides an impenetrable barrier to those elements that try to destroy your assets like UV radiation, salt air, acid rain, and smog/dirt.

Once applied you will realize cascade savings in operational overhead

- Maintenance frequency is less

- Flow rates are improved, reduced paraffin buildup, reduced downtime on infrastructure

- cleaning times can be cut by as much as 50%,

- reduced need for cleaning supplies, and

- machines run more efficiently resulting in lower utility costs.

Our product is moisture-cured, which is beneficial in hot, humid geographies like coastal zones and Southern states. It also enhances the appearance of the surface applied and projects a positive (image) “forever.” And is environmentally safe!

Lab Tests

- Thermal Shock – PASSED Liquid Nitrogen testing (9/2021)

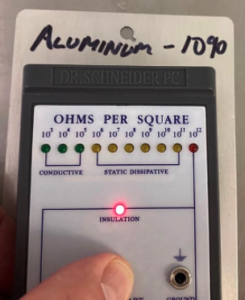

- Static Dissipative – PASSED testing (7/2021 A.I. Amazon, Google, Walmart)

- Continued testing to improve!

- Bidding? Call us with your required data point – We’ll meet the standards!

Test Procedure: Thermal Shock

TEST RESULTS:

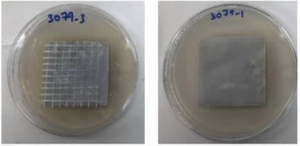

Table 1. Growth observation after 22 days if incubation at 36±1° C.

| Sample | Replicate | Growth Observation |

| Un-inoculated Control | 1 | No Growth |

| 2 | No Growth | |

| 3 | No Growth | |

| Test Sample | 1 (facing up) | Some visible growth |

| 2 (facing up) | No visible growth | |

| 3 (facing up) | No visible growth | |

| 4 (facing down) | Some visible growth |

Photo 1. Example test specimens (face 1 on the right and face 2 on the left) of P. aeruginosa before incubation.

Test Procedure: Static Dissipative

TEST PROCEDURE ASTM C1028: “Standard test method for determining the static coefficient of friction of ceramic tile and other like surfaces by the horizontal dynamometer pull-meter method”

TEST PROCEDURE ASTM C1028: “Standard test method for determining the static coefficient of friction of ceramic tile and other like surfaces by the horizontal dynamometer pull-meter method”

- A Chatillon DFIS 100 digital force gauge was used to measure each pull in pounds-force,

- A 3 x 3 1/8-inch piece of Neolite was used as the sensor.

TEST RESULTS: The average static coefficient of friction of four (4) pulls on each tile was as follows:

| As Received | After Cleaning | |

| Tile 1 | ||

| Dry | 0.79 | 0.80 |

| Wet | 0.79 | 0.80 |

| Tile 2 | ||

| Dry | 0.80 | 0.82 |

| Wet | 0.79 | 0.80 |

| Tile 3 | ||

| Dry | 0.79 | 0.82 |

| Wet | 0.78 | 0.80 |

The average static coefficient of friction of twelve (12) pulls was as follows:

| As Received | After Cleaning | |

| Dry | 0.79 | 0.81 |

| Wet | 0.79 | 0.80 |

Download the In-Depth Overview

Learn more about BallistiX products, solutions, preparation, and application instructions per your needs.